›

Informative

The Best Bifacial Solar Panels: Benefits, Costs, and Considerations

15 min read

Key Takeaways

- •Bifacial solar panels capture sunlight from both front and rear surfaces, generating 10-30% more electricity than traditional monofacial panels

- •These panels work best in elevated installations like ground-mounted systems, solar farms, and commercial rooftops with reflective surfaces

- •The International Technology Roadmap for Photovoltaic projects bifacial technology will capture 70% market share by 2030

- •While more expensive upfront, bifacial panels offer better long-term ROI through increased energy production and enhanced durability

- •Residential rooftop installations see limited benefits due to restricted rear-side light exposure

Bifacial Solar Panels: Complete Guide to Double-Sided Solar Technology

The solar industry is experiencing a revolution in efficiency, and bifacial solar panels are leading the charge. These innovative solar modules capture sunlight from both sides, delivering significantly more energy than conventional monofacial solar panels. With projections showing bifacial technology reaching 70% market share by 2030, understanding this double-sided solar solution has become essential for anyone considering solar power investments.

Unlike traditional panels that only generate electricity from their front surface, bifacial solar panels utilize both front and rear sides to maximize energy production. This breakthrough technology offers 10-30% more electricity generation compared to standard solar panel installations, making it an increasingly attractive option for commercial installations, utility-scale projects, and specific residential applications.

What Are Bifacial Solar Panels?

Bifacial solar panels are solar modules equipped with photovoltaic cells on both the front and rear surfaces, allowing them to capture sunlight and generate electricity from both sides. This fundamental difference sets them apart from monofacial panels, which feature an opaque backsheet that blocks light from reaching the rear side of the solar cell.

The technology behind bifacial panels isn’t entirely new – early versions existed in the 1960s. However, modern bifacial solar panels gained popularity with advances in PERC (Passivated Emitter and Rear Cell) technology, which improved the efficiency of crystalline silicon cells and made dual-sided energy generation commercially viable.

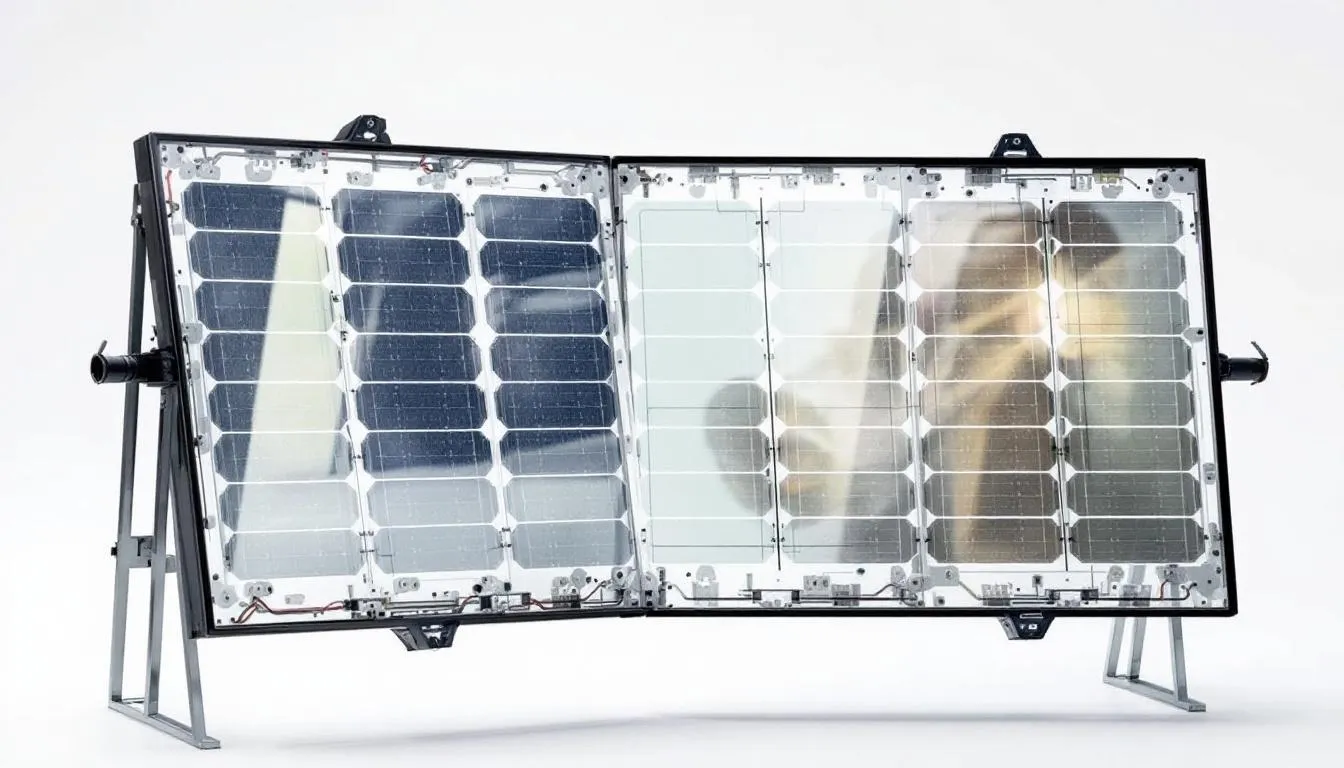

The image depicts the construction of bifacial solar panels featuring a transparent glass-glass design, showcasing solar cells on both the front and rear sides. This innovative design allows for enhanced energy generation by capturing sunlight from multiple angles.

The image depicts the construction of bifacial solar panels featuring a transparent glass-glass design, showcasing solar cells on both the front and rear sides. This innovative design allows for enhanced energy generation by capturing sunlight from multiple angles.

Physical construction distinguishes bifacial modules from traditional panels through their dual glass design or transparent polymer backsheet instead of the standard opaque backing. Most bifacial solar modules feature a glass-glass construction where tempered glass protects both surfaces, providing enhanced durability and allowing light transmission to the rear contact system.

Many bifacial panels adopt a frameless design, which not only improves structural integrity but also offers aesthetic appeal for commercial installations. This frameless bifacial modules design eliminates potential shading from frame edges on the rear surface while maintaining the mechanical strength needed for strong winds and weather resistance.

How Bifacial Solar Panels Work

The fundamental principle behind how bifacial solar panels work involves the photovoltaic effect on both surfaces of the solar module. The front side operates like conventional monofacial solar panels, directly converting sunlight into DC electricity through monocrystalline cells or other crystalline silicon technologies.

The rear side captures reflected light energy from surrounding surfaces through a process involving albedo – the measure of how much light a surface reflects. Different surfaces provide varying levels of reflectivity: fresh snow reflects approximately 85% of incident light, sand reflects around 40%, grass reflects 25%, and water reflects only 10%. This reflected light passes through the transparent polymer backsheet or dual glass design to reach the bifacial solar cells on the rear surface.

Light transmission through the transparent backing materials enables the rear sides of bifacial cells to generate additional power. The intrinsic thin layer structure of modern bifacial solar cells, particularly n-type silicon configurations, maximizes this rear-side energy absorption while minimizing potential induced degradation that can affect long-term performance.

The electrical characteristics of bifacial modules differ from traditional solar panels due to the additional current generated by the rear surface. This requires careful consideration during solar system design, as the total energy generation exceeds what front-side measurements alone would predict.

Types of Bifacial Solar Panels

Bifacial solar panels come in several construction and technology variations, each offering specific advantages for different applications and installations.

Construction-Based Classifications:

Glass-glass bifacial modules represent the most common construction type, featuring tempered glass on both front and rear surfaces. This dual glass design provides superior durability, weather resistance, and UV resistant properties compared to panels with polymer backsheets.

Glass-polymer configurations use traditional glass on the front with a transparent polymer backsheet on the rear. While potentially less expensive, these designs may have reduced longevity compared to full glass-glass construction.

Frameless bifacial modules eliminate the aluminum frame entirely, supporting the panel through specialized mounting systems. This design maximizes rear-side light capture by eliminating frame shadows while reducing surface area requirements.

Cell Technology Types:

MonoPERC half-cut bifacial cells represent a popular configuration, splitting standard solar cells into smaller segments to reduce resistive losses and improve efficiency. These panels typically achieve efficiencies in the 20-22% range.

N-type bifacial solar cells offer superior performance characteristics, including reduced light-induced degradation and better temperature coefficients. Advanced n-type technologies can reach efficiencies exceeding 22.5%.

Heterojunction (HJT) bifacial cells represent the cutting edge of bifacial technology, combining crystalline silicon with thin-film materials to achieve some of the highest efficiencies available in commercial panels.

Size and Power Variations:

Residential-scale bifacial panels typically range from 300-400 watts, designed for standard residential installations where space optimization matters.

Commercial and utility-scale bifacial modules often exceed 500 watts, taking advantage of larger cell configurations and optimized designs for ground mounts and large installations.

Performance and Efficiency Advantages

The performance benefits of bifacial solar panels extend well beyond simple energy output increases. Under optimal conditions, these panels deliver 10-20% more energy than equivalent monofacial panels, with single-axis tracking systems potentially achieving gains of 30-40%.

Energy generation improvements translate directly into better Levelized Cost of Energy (LCOE) calculations. Even with higher upfront costs, the increased electricity generation often results in superior long-term economics, particularly for commercial installations and utility-scale projects.

The image depicts a solar installation featuring bifacial solar panels mounted above a highly reflective white surface, designed to optimize energy capture from both the front and rear sides of the panels. This setup enhances electricity generation by utilizing reflected light to increase overall energy output.

The image depicts a solar installation featuring bifacial solar panels mounted above a highly reflective white surface, designed to optimize energy capture from both the front and rear sides of the panels. This setup enhances electricity generation by utilizing reflected light to increase overall energy output.

Performance varies significantly based on installation conditions and seasonal factors. Winter installations with snow cover can see dramatic increases in rear-side generation due to snow’s high reflectivity. Conversely, installations over dark soil or asphalt may see minimal bifacial gain.

Optimal tilt angles for bifacial installations often differ from monofacial configurations. While traditional panels typically perform best at angles matching local latitude, bifacial panels may benefit from different orientations that maximize both direct and reflected light capture throughout the year.

Real-world case studies from commercial installations demonstrate these performance advantages. Large-scale solar farms using bifacial technology with optimized ground cover and proper spacing consistently achieve the higher energy yields that make the additional investment worthwhile.

Installation Requirements and Considerations

Installing bifacial panels requires specific considerations that differ from traditional solar panel installations. The mounting height plays a crucial role in performance – panels should typically be installed at least 4 meters above ground to allow adequate light reflection to reach the rear surface.

Specialized mounting systems minimize shading on both surfaces. Unlike conventional installations where rear shading isn’t a concern, bifacial installations require narrower support rails and mounting systems that use corner-only vertical supports rather than continuous backing.

Ground surface preparation significantly impacts performance. Installing bifacial panels over highly reflective surfaces like white concrete, light-colored gravel, or specialized reflective ground covers can substantially increase rear-side energy production. Some installations invest in ground surface modifications specifically to enhance albedo.

Electrical considerations include accommodating higher DC current levels from the combined front and rear energy generation. Solar PV systems must be designed to handle the increased power output, including appropriate inverter sizing and electrical protection systems.

The manufacturing process for bifacial modules requires specialized handling during installation. The dual glass design, while more durable long-term, requires careful clamping techniques to prevent glass damage during mounting.

Applications and Use Cases

Commercial and utility-scale installations represent the primary applications where bifacial solar panels perform optimally. These large installations can justify the additional costs through economies of scale while taking advantage of optimal mounting configurations and ground preparation.

Ground-mounted residential systems and solar carports offer excellent opportunities for bifacial technology. These installations naturally provide the elevation and spacing needed for rear-side light capture while serving dual purposes as both energy generators and functional structures.

The image depicts a large-scale solar farm featuring bifacial solar panels mounted on tracking systems, designed to optimize energy generation by capturing sunlight from both the front and rear sides. The panels are installed over a highly reflective ground cover, enhancing their efficiency by utilizing reflected light for additional electricity production.

The image depicts a large-scale solar farm featuring bifacial solar panels mounted on tracking systems, designed to optimize energy generation by capturing sunlight from both the front and rear sides. The panels are installed over a highly reflective ground cover, enhancing their efficiency by utilizing reflected light for additional electricity production.

Agrivoltaics applications combine agriculture with bifacial solar installations, allowing farming activities to continue beneath elevated solar arrays. The dual-sided panels can capture reflected light from crops and soil while providing partial shade that can benefit certain agricultural applications.

Floating solar installations increasingly utilize bifacial technology to capture reflected light from water surfaces. While water has relatively low reflectivity compared to other surfaces, the large, uniform reflecting area can still provide meaningful rear-side generation.

However, standard residential rooftop installations face significant limitations with bifacial technology. Panels mounted close to dark roof surfaces with minimal clearance see little rear-side benefit, making the additional cost difficult to justify for most residential installations.

Cost Analysis and Economics

Current pricing for bifacial solar panels typically includes a premium of approximately $0.35-0.45 per watt over comparable monofacial panels. This premium reflects the more complex manufacturing process and specialized materials required for dual-sided functionality.

Regional pricing varies significantly. In markets like India, MonoPERC half-cut bifacial modules are available for around Rs. 24 per watt, while premium n-type bifacial technology commands higher prices reflecting its advanced performance characteristics.

ROI calculations must factor in the increased energy production over the system’s lifetime. Despite higher upfront costs, the additional electricity generation often results in payback periods of 3-5 years, particularly for commercial installations with optimal conditions.

Long-term warranty benefits add value to bifacial investments. Many manufacturers offer 25-30 year warranties on bifacial modules compared to 20-25 years for traditional panels, reflecting confidence in the durability of dual glass design construction.

Various markets offer subsidies and incentives for advanced solar technologies. These financial incentives can significantly improve the economics of bifacial installations, particularly for commercial and utility-scale projects.

Advantages and Disadvantages

Advantages

Bifacial solar panels deliver higher energy yield per square meter of installation space, making them ideal for space-constrained applications where maximizing efficiency matters most.

Enhanced durability comes from the dual glass design, which provides superior resistance to environmental factors including moisture, temperature cycling, and UV exposure. This construction often results in longer operational lifespans compared to traditional panels.

Better performance in diffuse light conditions gives bifacial panels an advantage during cloudy weather and in high-latitude locations where indirect sunlight represents a larger portion of total solar radiation.

The aesthetic appeal of transparent, frameless designs makes bifacial panels attractive for commercial and residential applications where visual impact matters.

Reduced temperature coefficient in many bifacial designs leads to better performance in hot weather conditions, maintaining higher efficiency as temperatures rise.

Disadvantages

Higher upfront costs and complex installation requirements can make bifacial panels economically challenging for budget-conscious projects or installations without optimal conditions.

Inconsistent rear-side power generation creates uncertainty in energy projections. Weather conditions, seasonal changes, and ground cover variations can significantly impact the bifacial gain, making performance predictions more complex.

Risk of glass damage from improper clamping during installation requires more careful handling and experienced installers familiar with dual-glass module requirements.

Limited benefits for standard residential rooftop applications mean many homeowners won’t see sufficient rear-side generation to justify the additional investment.

Higher system complexity requires specialized design expertise and understanding of bifacial-specific factors like albedo, mounting height, and optimal spacing considerations.

Leading Manufacturers and Market Trends

The global bifacial solar panel market is dominated by several leading manufacturers who have invested heavily in bifacial technology development. LONGi Solar, Trina Solar, Canadian Solar, JinkoSolar, and First Solar represent the top tier of bifacial solar panel manufacturers, each offering different technological approaches and efficiency levels.

Regional manufacturers are also making significant impacts in local markets. Companies like RenewSys Solar, Premier Energies, and Adani Solar have established strong positions in markets like India, offering competitive pricing and localized support for bifacial installations.

Market growth projections consistently show accelerating adoption of bifacial technology. The International Technology Roadmap for Photovoltaic industry analysis projects bifacial panels will capture approximately 70% of total solar panel production by 2030, representing a dramatic shift from current market shares.

Technology improvements continue driving cost reductions and efficiency gains. Manufacturers are focusing on optimizing the bifacial ratio, improving glass transmission properties, and developing more efficient bifacial cell designs to maximize rear-side energy capture.

Quality certifications and standards provide important guidance for buyers. Look for panels meeting IEC 61215 and IEC 61730 standards, along with manufacturer-specific quality certifications that demonstrate long-term reliability and performance guarantees.

Future Outlook and Innovations

The technology roadmap for bifacial solar panels includes ambitious efficiency improvement targets. Research institutions and manufacturers are working toward bifacial modules exceeding 25% efficiency while maintaining cost competitiveness with traditional technologies.

Integration with energy storage systems represents a growing trend. The higher energy output of bifacial installations makes them particularly well-suited for pairing with battery storage, creating more self-sufficient solar power systems.

The image depicts a modern building featuring integrated bifacial solar panels that serve both as architectural elements and energy generation systems. These bifacial solar panels are designed to capture sunlight from both the front and rear sides, maximizing energy production and enhancing the building's aesthetic appeal.

The image depicts a modern building featuring integrated bifacial solar panels that serve both as architectural elements and energy generation systems. These bifacial solar panels are designed to capture sunlight from both the front and rear sides, maximizing energy production and enhancing the building's aesthetic appeal.

Building-integrated photovoltaics (BIPV) applications offer exciting opportunities for bifacial technology. Transparent or semi-transparent bifacial panels can serve as windows, skylights, or facade elements while generating electricity from both sides.

Cost parity projections suggest bifacial panels may achieve price parity with monofacial alternatives within the next 5-7 years as manufacturing scales and technology matures. This cost reduction could accelerate adoption across all market segments.

Research developments in perovskite-silicon tandem bifacial cells promise even higher efficiencies. These next-generation technologies could push bifacial panel efficiency beyond 30% while maintaining the cost advantages of silicon-based manufacturing.

FAQ

Are bifacial solar panels worth the extra cost for residential installations?

For most residential rooftop installations, bifacial solar panels are not worth the extra cost. Traditional rooftop mounting positions panels too close to dark roof surfaces, preventing significant rear-side light capture. However, residential ground-mounted systems, carports, or elevated installations with reflective surfaces underneath can justify the additional investment through meaningful bifacial gains.

What is the minimum height required for bifacial panel installation to be effective?

Bifacial panels should be mounted at least 4 meters above ground for optimal rear-side light capture. However, meaningful bifacial gains can be achieved at lower heights (2-3 meters) depending on ground reflectivity and panel spacing. The key is ensuring adequate clearance for reflected light to reach the rear surface without excessive shading from mounting structures.

How do weather conditions like snow and rain affect bifacial panel performance?

Snow significantly enhances bifacial panel performance due to its high reflectivity (up to 85%), often resulting in exceptional rear-side generation during winter months. Rain generally has minimal impact on bifacial performance, though it can temporarily reduce rear-side generation by making surfaces less reflective. The self-cleaning effect of rain on panel surfaces often provides long-term benefits for both front and rear-side generation.

Can existing solar mounting systems be used for bifacial panels?

Most existing mounting systems can accommodate bifacial panels, but modifications may be needed to optimize performance. The key requirements include minimizing rear-side shading through narrower rails or modified support structures, ensuring adequate ground clearance, and accommodating the dual-glass construction. Some installations may benefit from specialized bifacial mounting systems designed to maximize rear-side light exposure.

What maintenance requirements are different for bifacial panels compared to traditional panels?

Bifacial panels require cleaning of both front and rear surfaces to maintain optimal performance, effectively doubling the cleaning requirements. The rear surface can accumulate dust and debris that reduces light transmission and rear-side generation. However, the dual glass design typically makes cleaning easier and more effective than traditional panels with textured backsheets. Regular inspection of mounting systems is also important to ensure rear-side clearance remains unobstructed by vegetation or debris accumulation.